How wall clocks are made | Ariel Quartz’s Manufacturing Process

It might interest you to know that the global wall clock market is expected to grow to $5.7 billion by 2027. From classic designs to contemporary digital styles, wall clocks are more than mere devices to keep time; they serve as fashion accessories, atmosphere creators, and marketing devices.

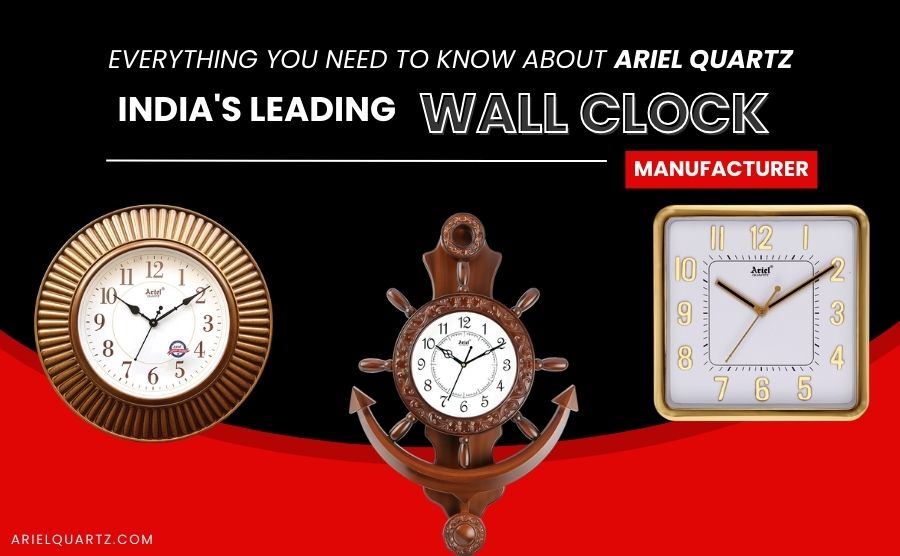

At Ariel Quartz, a leading wall clock manufacturer in Morbi, India, we capture the spirit of each wall clock by combining meticulous engineering design with artistic flair. Since over 80% of the globe’s population owns at least one wall clock, there is an ever-increasing demand for unique, quality designs. From initial brainstorms to the final touches of quality control. We make sure that every single clock we produce reflects a unique style and enduring personality.

Explore our seamless production process and discover why Ariel Quartz is a trusted name in the wall clock industry.

Manufacturing Process of Wall Clock

Conceptualisation

Each clock is produced defining the shape, style, and functionality of the final product through a thorough design and planning phase.

Market Research & Concept Development – Consumer preferences, trends, and practical use cases are analyzed, incorporating concepts necessary for graphical design.

Blueprint Creation – The technical drawings along with the 3D digital model are created by imagining the required measurement ratios and assembling portions.

Material Selection – Smooth surface ABS plastic, as well as wood and metal finishes, are selected regarding the required style and durability of the clock.

This stage ensures that each Ariel Quartz clock is aesthetically appealing, structurally sound and functional as well.

Molding

After having a finalized design, the clock frame and body can be appropriately shaped through molding all the while production begins.

Precision Moulding Process – Quality molds made for particular parts form different shapes of whole parts ranging from circular and square to even custom-made hexagonal types.

Material Processing – The materials selected are melted and turned into liquid form which is injected into a packet mould shape of the clock’s frame where after cooling and setting it becomes strong and permanently loose.

Cooling & Trimming – These components go under the process of moulding where they are cooled down and then set leads to them solidifying after which they are filled then smoothed out by removing everything covering excess material.

Surface Treatment - Before the paint is applied to the clock, the surface must be treated and prepared to enhance adherence in subsequent processes.

This part of the process includes building the basic structure of the clock and guarantees accuracy during construction.

Here are some of the most loved wall clock designs:

Colouring and Branding

At this stage, the clocks are painted and individual customization is done based on client specifications.

Paint Application & Coating - Specially formulated high-durability spray paints with fade-resistant pigments are applied in several coats to get the desired, long-lasting colour and protection.

Customization & Branding - Promotional wall clocks and corporate wall clocks are produced with company logos, signature styles, and other designs for specific branding purposes.

Finishing Touches - To make it scratch-proof as well as guard against wear and tear from the environment, a clear coat of paint is used to ensure the product lasts longer and is more durable.

At this stage, the outward appearance of the clock is changed so that it can be accentuated with the company's brand and logos.

Glass Cutting Technology

Intricate details along with unique patterns are cut onto the glass using high-end glass-cutting technology enhancing the structural beauty of the clock.

Precision Glass Cutting- The glass face of the clock is cut out using glass engraving for superior transparency combined with sharp edges.

Etching for Decoration - A design is etched into the glass surface with a laser or mechanical engraver, creating bumps and grooves to give it more detail.

Light Reflection Optimization – The engravings are done to capture and manipulate light, thus creating a beautiful and elegant appearance.

Polishing & Cleaning – Each engraved glass is individually polished to extract any remnants and dust, achieving a flawless clean.

This step guarantees that the glass components for the clocks are refined, durable, and aesthetically pleasing.

Assembling

In this last phase, the unit is assembled using all the manufactured components to produce a functional clock.

Component Alignment – The clock’s mechanism, dial, frame, hands, and embellishing features are brought together to form the clock's basic structure and are locked in place with screws.

Timekeeping Accuracy Testing – The movement strategy is set for accurate time counting, with possible changes in the future.

Durability & Stability Check – The new timepiece is checked for structural integrity and tested for motion and orientation.

This step makes sure fully functional, eye-catching Ariel Quartz wall clocks are ready to be distributed to retailers after the final quality check.

Quality Check

1. Visual Inspection

Ensuring a flawless finish by checking for scratches, cracks, and inconsistencies in design and materials.

2. Functional Testing

Verifying clock mechanisms, time accuracy, and smooth operation of all components.

3. Hand Movement & Alignment Check

Ensuring precise alignment and smooth motion of hour, minute, and second hands.

4. Durability & Stability Testing

Assessing strength, resistance to impact, and long-term reliability under different conditions.

5. Sound & Noise Level Inspection

Checking for minimal ticking noise and ensuring silent or smooth operation as per design.

6. Packaging & Accessories Verification

Reviewing packaging quality, included accessories, and secure placement for safe transit.

7. Final Random Sampling

Conducting a last quality check on randomly selected units to ensure overall consistency.

These steps ensure that every Ariel Quartz wall clock is a masterpiece, creating a perfect harmony of modern sophistication and timeless beauty in any setting.

Why Choose Ariel Quartz’s Wall Clock?

Ariel Quartz is one of the leading wall clock manufacturers in Morbi, India with over 40 years of experience. Quality being in our DNA, each Ariel Quartz wall clock is crafted with precision. With us, you will get durability and an eye-catching collection of 15+ premium wall clock categories. Whether you are looking for casual home decor, corporate gifting, or branding, our wall clocks are the best to choose with a one-year manufacturing warranty.

Wrapping It Up

In summary, starting a brainstorming design to bring it to life, the whole manufacturing process of a wall clock is truly magical. Being one of the top wall clock manufacturers in Morbi, India, Ariel Quartz understands each step needs precision care and quality control during this process. Our dedication and passion make our clocks stand out in the market in every parameter including style, aesthetics, and functionality. Want to explore the most promising collection of wall clocks? Download our catalogue now.

![The Best Wall Clock Shapes to Elevate Your Decor [Updated]](https://technobytesllp.in/ariel-quartz-admin/public/images/blog/g0dPNH4vMj4E6y76mbs1SpDxfnupSiSXg3RuwEq6.jpg)

![Vastu Principles For Wall Clocks That You Must Know [Updated]](https://technobytesllp.in/ariel-quartz-admin/public/images/blog/hCEm84AB5tDf5iGGpCP32AJCGDgKH1lMn0Pq3MSF.jpg)